ExoAir® Flex Foam

Flexible, Low-Expansion Polyurethane Foam

ExoAir® Flex Foam

Flexible, Low-Expansion Polyurethane Foam

A single-component, high performance, gun-grade polyurethane flexible foam that performs as a thermal barrier. With an industry leading movement range of +/-15%, ExoAir® Flex Foam protects against thermal expansion and contraction around windows, doors, base plates, joints, penetrations and cracks. ExoAir Flex Foam is CFC-free and can be applied over a wide temperature range.

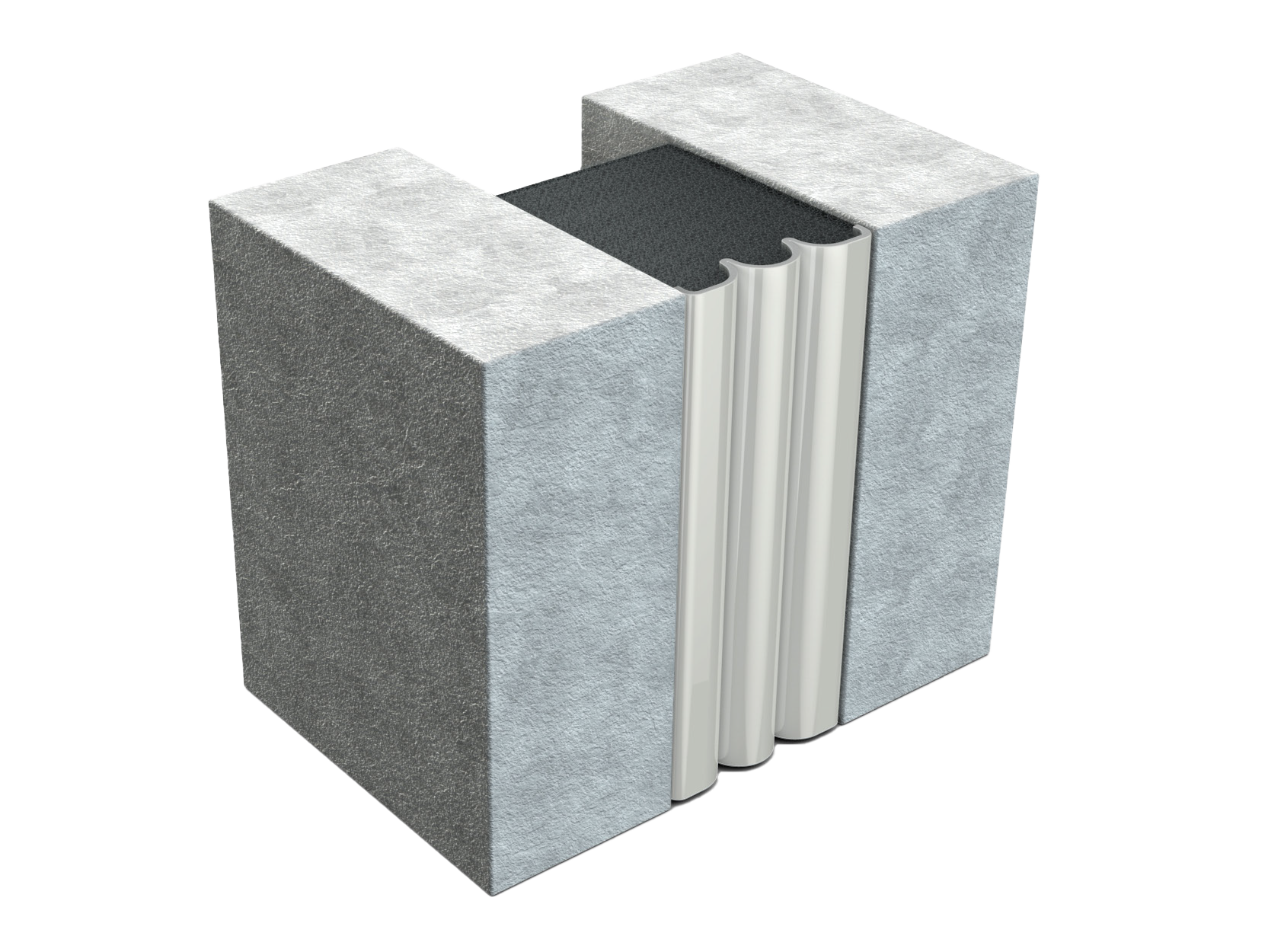

Download Data Sheet Find a Rep or Distributor Willseal® Seismic

Willseal® Seismic

ExoAir® 230 / 230LT

ExoAir® 230 / 230LT

ExoAir® 110AT

ExoAir® 110AT

Securock® ExoAir® 430

Securock® ExoAir® 430

ExoAir® 130

ExoAir® 130

ExoAir® LEF

ExoAir® LEF