Deck Coatings: Top 5 Installation Practices

Here are some common deck coating mistakes in the field and tips to avoid them, and also top 5 deck coating installation practices.

Here are some common deck coating mistakes in the field and tips to avoid them, and also top 5 deck coating installation practices.

Deck coatings, also known as traffic coatings and waterproofing membranes, protect concrete decks, parking garages and similar structures from damage and water infiltration caused by frequent vehicular and pedestrian traffic.

While these materials can be sensitive to temperature, moisture and other conditions out of your control, there is a lot that contractors and installers can do to minimize risk of product failure and ensure the longevity of the waterproofing application.

The top 5 areas in deck coating installs where I see mistakes though are related to the concrete surface profile, substrate preparation, drains, protrusions and product mixing, so here are the proper deck coating practices to avoid these challenges.

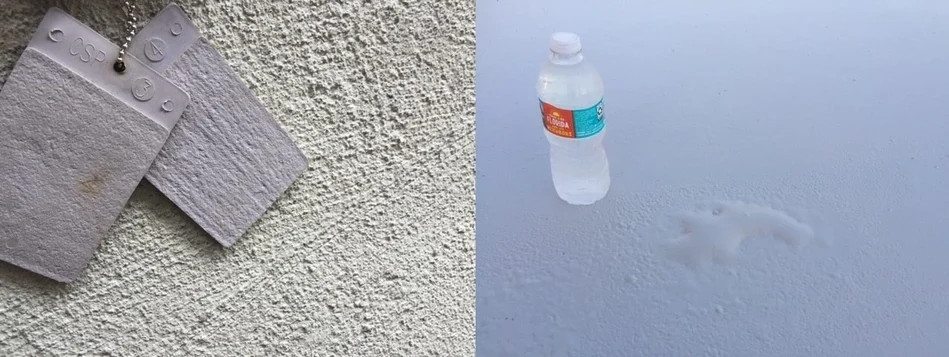

Concrete surface profile (CSP) is recommended to be an ICRI (International Concrete Repair Institute) concrete surface profile of 2 to 4. If the concrete is not within CSP 2 to 4 or the manufacturer's recommended profile, it should be repaired using an appropriate concrete patching mortar or sand-filled concrete epoxy.

If the applicator fails to have the concrete repaired, the coating may be applied too thick, leading to bubbles, blisters and pinholes, and the possibility of longer cure times for single-component systems. To help determine your concrete’s profile, I recommend using ICRI’s concrete surface profile chip set for comparison.

When prepping a concrete deck to be coated, applicators either shot blast or grind the deck to get the proper concrete surface profile. It is important to remember to pressure clean the decks after this process to remove any laitance or dust. If a waterproofing material like a liquid rubber deck coating or polyurethane membrane is applied over dust, it will not have proper adhesion. Dust creates a bond breaker, forcing the coating to stick to the dust particles, not the deck itself. This barrier could cause the membrane to eventually delaminate or separate from the deck, requiring a complete reapplication of the coating system.

Far too often, I see drains that are placed above the deck surface. If it is more than 1 in. higher than the deck, the water will only drain once the water reaches that inch in depth.

Ponding water can be very detrimental to the success of your deck. Moral of the story: drains must be flush with the concrete deck.

It is common to find exposed rebar or rusty nails/tie downs protruding from the deck surface. However, any defects like these must be removed or covered with a waterproof epoxy primer or epoxy filler prior to application of the deck coating. Otherwise, the rust can bleed through and compromise the adhesion of the waterproofing system.

Proper mixing of liquid deck coatings is extremely important. If applicators are not taking the proper mixing times seriously, it can affect the dispersion of colors, as well as the cure of the products.

Reference the manufacturers' website for mixing instructions as part of the specific product's application instructions.

Construction products, especially deck coatings, are only as good as their application. This goes for the cleaning and preparation stages of the process as well.

These initial steps are most important to ensuring the long-term success and warranty of a deck coating system. If you have questions about proper substrate preparation or coating installation, feel free to call your local Tremco representative.