Pinholes: Cause and Control

There are many factors that may contribute to or cause pinholing in a cementitious substrate. Here are the three most common culprits and how to avoid them.

There are many factors that may contribute to or cause pinholing in a cementitious substrate. Here are the three most common culprits and how to avoid them.

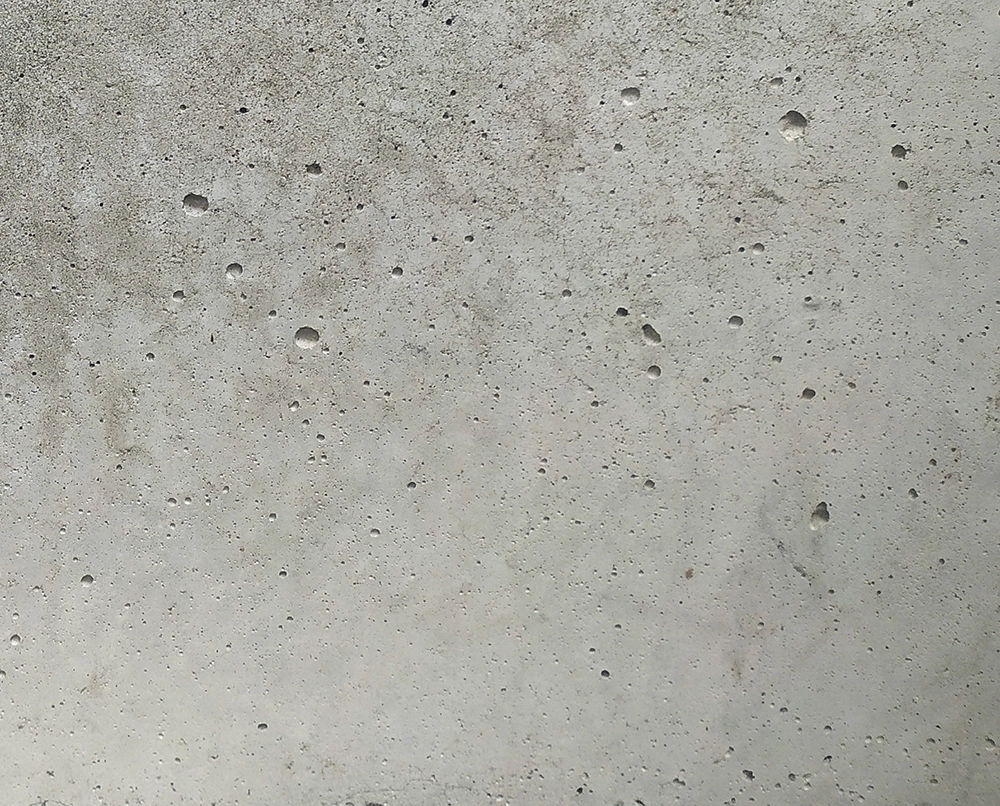

In deck and traffic coatings, it is not uncommon to see pinholes in the surface. Pinholes are defined as very small holes that form from the substrate and transfer through the polyurethane waterproofing membrane or coating on top. The substrate most often associated with pinholing is concrete, but it can also occur with other porous or cementitious materials.

There are many factors in concrete deck construction that may contribute to pinholing. Three of the most common culprits include:

1. Concrete Voids

1. Concrete VoidsAfter a concrete slab has cured, there are often voids in the surface which are known as “bug holes.” These small imperfections in the concrete cannot always be filled with a liquid membrane or coating, so air can become trapped inside them. As the concrete heats up, the air forces itself through the membrane or coating, puncturing the material from the inside causing the pinhole.

The aggregate used within the concrete mix design may also lend itself to pinholes. Some aggregates retain moisture at a higher concentration thus leading to outgassing as the concrete increases in temperature.

The concrete mix design and general porosity of the finished product can also impact the risk for pinholing. The air and any latent moisture present in the concrete slab will outgas causing pinholes in the membrane or coating.

Thankfully, pinholes can be prevented. Here are three ways to control pinholing in your substrate:

Thankfully, pinholes can be prevented. Here are three ways to control pinholing in your substrate:

One of the simplest ways to alleviate pinholing in polyurethane membranes and coatings is to complete the- waterproofing application when the substrate is cooling, generally in the early evening or overnight.

The use of a moisture- or vapor-mitigating primer prior to the application of the membrane or coating will help lock down the substrate. Proper primer installation can act as a sealer for concrete to prevent outgassing.

Speak with the waterproofing manufacturer early in the process and at job site meetings to ensure proper steps are taken to control pinholing before it becomes an issue.