Blindside Waterproofing: The Ultimate Architects' Guide

Explore the key differentiators among blindside waterproofing options and best practices for mitigating risk and moisture infiltration.

Explore the key differentiators among blindside waterproofing options and best practices for mitigating risk and moisture infiltration.

When your project requires blindside waterproofing, don’t jump into it blind. With numerous product technologies and types used in below-grade waterproofing, it is crucial to understand how their performance characteristics will impact your waterproofing system design. Read on to learn the differences between blindside waterproofing options and best practices for managing risk and preventing moisture infiltration.

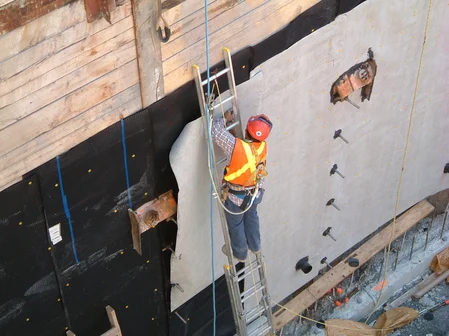

Blindside waterproofing is used in below-grade construction situations when excavation outside of foundation walls is not feasible. This method is common in urban areas where a project has close proximity to bordering structures or there is little room for maneuvering heavy equipment. Here is the basic blindside construction process:

When rebar is installed for preparation of the structural wall, or when shotcrete or concrete is placed against the waterproofing, there is a risk of damage to the waterproofing membrane.

Several liquid and sheet waterproofing technologies are designed to help overcome these challenges, so designers and specifiers should be aware of their features to identify which blindside solution is best for a particular installation.

Here are some of the waterproofing systems that can work in below-grade and blindside waterproofing applications. For more details on Tremco's below-grade offerings, download our Below-Grade Waterproofing guide here.

Spray-Applied Membranes

Liquid spray-applied membranes, like TREMproof 260, provide a monolithic coating with a chemical bond to the concrete. A spray-applied waterproofing system is easier to detail than other methods, and when using a co-spray accelerant, such as calcium chloride, allows the membrane to cure quicker. The material is typically sprayed on a carrier sheet. Some manufacturer systems spray material directly on the drainage mat, which may not be optimal due to the dimples on the drainage. It is best to spray onto a flat surface to allow for the correct mil coverage and consistency across the entire surface.

Bentonite-Based Sheet Membranes

Bentonite sheet membranes, including Tremco's Paraseal line, have a long history of success due to their controlled mil thickness and multiple layers for waterproofing redundancy, such as an HDPE material with bentonite. When the bentonite is hydrated, it swells to create an impermeable barrier. Some manufacturers also offer variations that are usable in salt water, which are ideal in coastal areas. These waterproofing systems tend to be chemical-resistant and are particularly robust for methane mitigation when heat welded, a common practice on the west coast.

Bentonite sheet membranes can have some drawbacks, however. They require compaction to the concrete, and installation is typically a labor-intensive process that requires a specialized trade. For all applications, care needs to be taken to prevent the bentonite from prematurely hydrating, so it needs to be covered with a plastic protection sheet if wet weather is imminent in exposed conditions.

Asphaltic Sheet Membranes

Derived from the roofing industry, asphaltic sheets are a reliable blindside waterproofing option when you need a flexible material or when applying in cold temperatures. They are comprised of a modified asphalt-polymer blend with reinforced fiber and are adhered to concrete with a mechanical bond. Seams are heat-welded together, which can make the application process more labor intensive.

Plastic Sheet Membranes

For high strength, consider sheet waterproofing membranes made with synthetic materials such as polyethylene, polymers and resins. Their fabric or adhesive layers can provide a mechanical or chemical bond to concrete. They are impact- and chemical-resistant and highly effective in low-temperatures. However, these plastic sheets can be more complicated to install due to additional detailing involved with penetrations.

Synthetic Rubber Sheet Membranes

Synthetic Rubber Sheet Membranes

Synthetic rubber sheet waterproofing membranes include flexible and durable materials, such as EPDM, that bond mechanically to concrete. They have excellent water resistance and can withstand UV and extremely high temperatures. Some products, like TREMproof Amphibia, even have self-healing and self-sealing capabilities to remain watertight even in the case of small incidental penetrations.

When deciding which route to go in blindside waterproofing product selection, consider these key project factors:

Also check the products’ adherence to ASTM testing to ensure it fits your project requirements. Some important performance characteristics related to physical properties include:

After selecting the best product or system for your project, the installation itself has risks that can inhibit the waterproofing's effectiveness as a barrier to moisture intrusion. However, the design and construction teams can minimize the likelihood of errors in the field by following these best practices.

The purpose of the pre-con meeting is to establish communication between all trades and parties involved prior to construction and ensure that everyone understands who is responsible for each task and when completion should occur. This step integral to proper trade sequencing and detailing of waterproofing systems.

The pre-construction meeting should include all of the following activities:

Discover five additional ways the specifier can help prevent leaks.

In waterproofing, the surface to be covered must be smooth, firm and free from mud, loose mortar, wires, metal projections or any other substances that might prevent placement of membrane. With a wood lagging wall, no gaps greater than 1 in. are acceptable. Any protrusions or changes in plane greater than ¼ in. should be made even with mastic, sealant or plywood.

The lack of proper detailing and installation of gaskets or waterstops in the structure are the most common causes of ground water ingress. Here are the key areas below-grade particularly prone to moisture infiltration:

Lastly, it is important that your below-grade project is protected, as such a vulnerable stage cannot be easily remediated. When looking for a blindside waterproofing product warranty, consider a single-source warranty that offers watertight leak coverage, including at seams, details and transitions.

Blindside waterproofing can be a challenging but necessary method of below-grade waterproofing. It is crucial to ensure your system is not compromised by selecting the best product solution for your project and properly detailing areas susceptible to moisture intrusion, as it can be very tricky and expensive to make any repairs after the fact.

View our Below-Grade Waterproofing Brochure to see all of Tremco's waterproofing offerings.